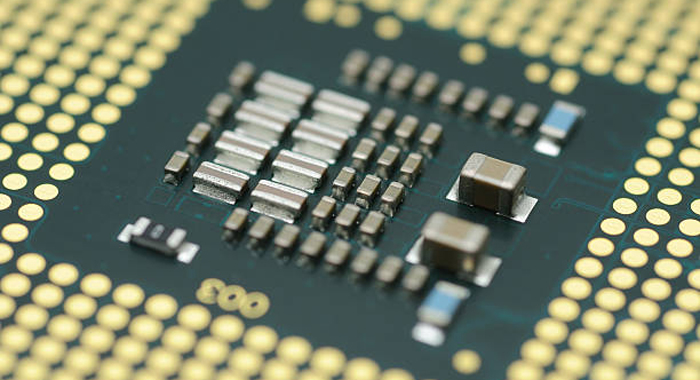

SMD ceramic capacitors are electronic components that are currently used in large quantities and are widely used. Thanks to its advantages of small size, large specific volume, long life, and high reliability, MLCC accounts for about one-third of the passive component market and has penetrated into almost all electronic circuits. As electronic terminals move toward miniaturization and precision, MLCCs have gradually become an indispensable part of various fields.

What is MLCC?

MLCC is one of the passive components. It is composed of ceramic dielectric films with printed electrodes stacked in a dislocated manner, sintered at high temperatures to form a ceramic sheet, and then sealed with a metal layer.

Passive components refer to electronic components that do not generate any form of power internally during operation. They do not consume electrical energy and only require input signals to function normally. Capacitors are one of the most popular passive components. Capacitors can be divided into polarized capacitors and non-polar capacitors. According to different media, they can be divided into ceramic capacitors, aluminum electrolytic capacitors, tantalum electrolytic capacitors, and polyester film capacitors.

Source: Internet

Driven by market demand, the market size of small-volume ceramic capacitors is accelerating. Among them, MLCC occupies a larger share. MLCC can be mounted on PCBs and hybrid integrated circuit substrates, conforming to the trend of lightweight and miniaturization in consumer electronics, and has become the main force of ceramic capacitors.

Capacitor Parameter

According to Temperature characteristics, material, and production process: NPO/C0G, Y5V/Z5U, X7R/X5R, etc. Based on the material size: 0402, 0603, 1005, 1608, 2012, 3216, 3225. What role do different parameters mean?

Capacitors with different filling media have different capacities, dielectric losses, capacity stability, etc. Therefore, when using capacitors, different capacitors should be selected according to their different functions in the circuit. NPO capacitors are among the most stable in capacitance and dielectric loss. When the temperature is from -55℃ to +125℃, the capacity change is 0±30ppm/℃, and the change in capacitance with frequency is less than ±0.3ΔC. Its drift or hysteresis is less than ±0.05%, which is negligible compared with film capacitors greater than ±2%.

Murata Ceramic Capacitors

With different packaging forms, the characteristics of capacitance and dielectric loss changing with frequency are also different. Larger package sizes have better frequency characteristics. NPO capacitors are suitable for tank capacitors in oscillators and resonators, as well as coupling capacitors in high-frequency circuits.

X7R capacitors are called temperature-stable ceramic capacitors. When the temperature is from -55℃ to +125℃, the capacitance change is 15%. It should be noted that the capacitor capacity change is non-linear at this time. Under different voltage and frequency conditions, the capacitance is different and changes with time. It changes by about 1%ΔC every 10 years, which means a change of about 5% in 10 years. X7R capacitors are mainly used in industrial applications with low requirements, and under the condition that the capacitance change is acceptable when the voltage changes, its main feature is that the capacitance can be larger under the same volume. It is suitable for decoupling and smoothing. There are also voltage-resistant varieties such as 250V, 630V, 1000V, and 2000V.

Y5V capacitors are general-purpose capacitors with certain temperature limits. Within the operating temperature range of -30°C to 85°C, their capacity changes from +22% to -82% and the dielectric loss is 5%. The high dielectric constant of Y5V allows capacitors up to 100µF to be displayed in a smaller physical size. It is suitable for decoupling and smoothing.

MLCC Applications

The upstream of the MLCC industry chain is mainly ceramic powder and electrode materials. The production of ceramic powder requires barium titanate, strontium zirconate, barium per titanate, etc. The representative manufacturer is Murata.

There are various methods for preparing ceramic powder, and the hydrothermal method has gradually become mainstream in the industry. The concentration of suppliers of ceramic powder materials is relatively high. Since ceramic powders have very high requirements for purity, particle size, and uniformity, the relevant technologies and processes have high thresholds, resulting in an oligopoly competition among MLCC ceramic powder suppliers.

MLCC Applications

In contrast, the competitive landscape of midstream MLCC is relatively stable. The first echelon includes Murata and TDK, and Samsung, KEMET, AVX, and YAGEO are in the second echelon. Downstream applications cover consumer electronics, automotive electronics, new energy, aerospace, industry, and other fields.

Continuous Innovation In Consumer Electronics Increases MLCC Usage

Consumer electronics products tend to be wireless charging, lightweight and portable, with multiple cameras and fingerprint recognition. More electronic components are needed for voltage stabilization, current stabilization, and filtering to ensure the normal operation of terminal equipment. Faster connections and more powerful processing capabilities require more passive components, so the use of MLCCs is accelerating.

Popularization of New Energy Vehicles Drives Demand for MLCCs

Automotive electronics mainly include engine control systems, chassis control systems, body electronic control systems, safety and comfort systems, autonomous driving systems, and network connection systems. New energy vehicles have begun to become popular. As consumers' demand for functions continues to escalate, the automotive demand for passive components represented by MLCC will continue to expand as the penetration rate of electric vehicles increases.

5G Opens Up New Space for MLCC Growth

5G base station is the core equipment of 5G network. It mainly provides wireless coverage and realizes wireless signal transmission between wired communication networks and wireless terminals. Since 5G base stations have the characteristics of high accuracy and small coverage radius, the number of 5G macro base stations required for the same signal coverage area is far more than the number of 4G macro base stations.

In order to meet the ultra-high user experience rate requirements in the 5G era and achieve ultimate information transmission speed and extremely high information transmission quality, large-scale antenna array technology has emerged, resulting in an increase in the usage of MLCCs in single base stations.

MLCC Selection

There are many models of MLCC, and their functions include filtering, oscillation, energy storage, etc. How do you choose the appropriate MLCC for different circuit designs?

First, determine the capacity and capacity error of the capacitor. MLCC has a wide range of capacity options, ranging from as low as 0.1pF to as high as hundreds of uF. The capacity error is the maximum allowable deviation range between actual and nominal capacitance. MLCCs are mostly used as precision capacitors, so generally, the allowable error needs to be smaller.

Class B (±0.1pF), Class C (±0.25pF), Class D (±0.5pF), Class F (±1%), Class G (±2%), Class J (±5%), Class K (±10%), M level (±20%), Z level (-20% to +80%)

DC bias characteristics also need to be considered when selecting capacity. The capacitance of MLCC changes depending on the applied voltage. According to different dielectric materials and process technologies, MLCC can be divided into temperature compensation type and high dielectric coefficient type. Among them, DC bias characteristics generally appear more on high-dielectric-coefficient MLCCs, but rarely appear on temperature-compensated MLCCs.

In addition, the withstand voltage (DWV) also needs attention. The voltage resistance performance of a capacitor refers to the maximum voltage that its ceramic dielectric can withstand in working conditions, that is, the breakdown voltage, which is also the limit voltage of MLCC. For MLCCs with the same structure, medium, and capacity, the higher the withstand voltage, the larger the volume.

4.7UF 35V X5R 0603

Factors worth considering include dielectric material, size, temperature coefficient, etc.

Each material of MLCC has unique performance characteristics. Generally speaking, the higher the dielectric constant (K value) of the material, the worse the stability, reliability, and durability of the capacitor. The temperature coefficient refers to the relative change in capacitance for every 1°C change in temperature within a certain temperature range. Of course, the smaller the temperature coefficient, the better.

High-frequency capacitors with NPO/COG dielectric have extremely high stability and a small temperature coefficient. It almost does not change with changes in temperature and voltage. Its capacity accuracy is mainly ±5%. When the capacity is less than 10pF, grade B (±0.1pF), grade C (±0.25pF), and grade D (±0.5 pF) are three precisions. However, this type of MLCC capacitor is expensive and has a small capacity.

X7R/X5R dielectric medium-frequency capacitors have average stability and medium temperature coefficient. Its temperature coefficient is ±15%, and its capacitance is relatively stable. Under special circumstances, products with J-level (±5%) accuracy can be provided.

Low-frequency capacitors with Y5V/Z5U dielectric have poor stability and large temperature coefficients. This type of MLCC is generally only suitable for various filter circuits. Its capacity accuracy is mainly Z-level (-20%~+80%), and products with ±20 accuracy can also be selected. However, this type of MLCC has a large capacity and low price and can replace low-capacity aluminum electrolytic capacitors.

After determining the parameters, the final step is to select the manufacturer. The first-tier manufacturers represented by Murata, Taiyo Yuden, and TDK have strong technical strength and production scale, focusing on high-end automotive and industrial control MLCCs. The production capacity of Samsung, Yageo, and Walsin is not small, but there is still a certain gap between the technical level and Japanese manufacturers.

Conclusion

In short, when choosing MLCC, you need to combine your own engineering needs and choose suitable parameters to achieve the highest effect. In addition to the parameters mentioned above, it may also be necessary to consider the insulation resistance, frequency characteristics, loss, and other performance parameters of MLCC. Finally, in order to meet the normal progress of the project, it is also very important to choose a supplier that can continuously provide high-quality electronic components. Hard Find Electronics LTD. is able to continually supply MLCC at a stable price to support your business and project smoothly.