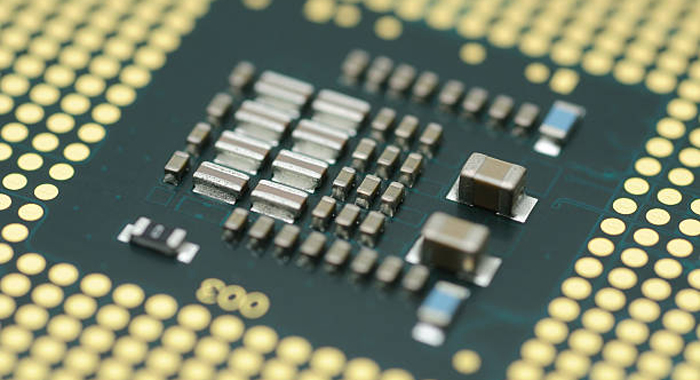

Almost all electronic devices used passive electronic components. Ceramic Capacitor is one of the most essential parts in a variety of applications. They are used for bypassing, decoupling, filtering, and energy storage. With the development of the 5G and automotive electronics, the demand for MLCCs is in steady growth.

Ceramic Capacitors Introduction

Ceramic capacitors are made using a mix of ceramic and metal materials, and have a variety of advantages over other types of capacitors such as electrolytic and film capacitors. Features low cost, high dielectric strength, high stability, high operating temperature, and tiny in size, they are well-suited for use from high-frequency RF applications to low voltage power supplies.

Source: Internet

Different types of ceramic capacitors use for various applications.

1. Ceramic Disc Capacitors: These are the most basic type of ceramic capacitor and are used for bypass, decoupling, and coupling applications. They are also used for filtering and timing circuits.

2. Ceramic Chip Capacitors: These capacitors are made from a monolithic ceramic material and have a low profile. They are used in high-frequency circuits, oscillators, and filters.

3. Ceramic Multilayer Capacitors: These capacitors are made from multiple layers of ceramic material and are used for high-frequency and high-voltage applications. They are also used in power supplies and other filtering applications.

4. Ceramic Trimmer Capacitors: These capacitors are used to adjust the frequency of circuits and are adjustable by hand. They are often used in radio frequency (RF) applications.

5. Ceramic Polymer Capacitors: These capacitors are made from a combination of ceramic and polymer materials and are used for high-frequency and high-voltage applications. They are also used in power supplies and other filtering applications.

Source: Internet

Multilayer ceramic capacitor (MLCC) and ceramic disc capacitors are commonly used in modern electronics. MLCCs are the most produced capacitors, with an estimated 1 trillion devices produced annually. They are made in surface-mounted (SMD) technology and are highly sought after due to their small size. Ceramic disc capacitor has capacitance values ranging from 1nF to 100µF, and they have a low maximum rated voltage. Additionally, ceramic capacitors are non-polarized and can be safely connected to an AC source. Furthermore, they boast great frequency response due to their lack of parasitic resistance or inductance.

Applications of Ceramic Capacitors

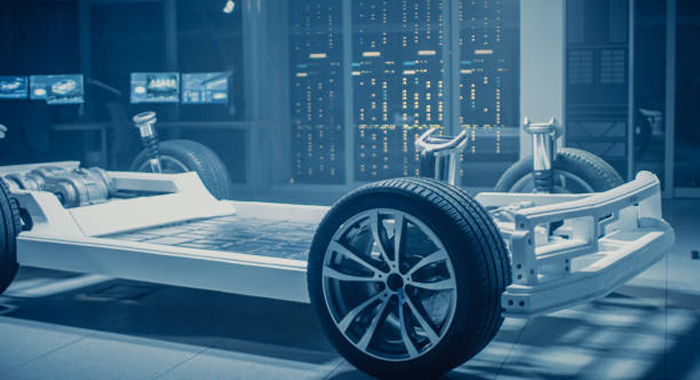

Ceramic capacitors are used in a wide range of applications, including power supplies, electronics, and automotive. In power supplies, ceramic capacitors are used to smooth out high-frequency noise and provide a stable voltage. In electronic circuits, they are used to filter signals and reduce noise. In automotive applications, ceramic capacitors are used to absorb voltage transients and protect sensitive components.

Source: Internet

In the automotive field, the most common application is in the powertrain, where ceramic capacitors are used to regulate the power supply and provide stability for the systems in the car, such as the powertrain control module and the engine control unit. In electric and hybrid vehicles, ceramic capacitors are used to store energy and regulate power delivery, allowing the vehicle to be more efficient and reduce emissions.

They are also used in many other automotive systems such as airbags, ABS brakes, and even in audio systems. An example of a ceramic capacitor used in an electric vehicle is the supercapacitor. Supercapacitors are able to store and discharge large amounts of energy quickly, making them ideal for electric vehicles since they can provide a burst of energy during acceleration or regenerative braking.

Selection Criteria

Different applications require various ceramic capacitors. Selecting the right component is the way to help you get twice the result with half the effort. When selecting a ceramic capacitor, it is important to consider several factors such as capacitance, voltage rating, and temperature range.

The capacitance of a capacitor is measured in Farads, and the higher the Farad rating, the more charge the capacitor can store. The voltage rating of a capacitor is the maximum voltage it can handle without damage and should be selected based on the application. The temperature range is also important and should be selected based on the environment in which the capacitor will be used.

For power applications, it required ceramic capacitors with high-temperature ratings, high voltage ratings, and low ESR values. Examples include X7R, Y5V, and Z5U dielectric capacitors.

For high-frequency applications, you should look for ceramic capacitors with low parasitic inductance, low ESR values, and high-frequency ratings. Examples include SMD chip capacitors and multilayer ceramic capacitors.

For decoupling applications, capacitors with low inductance and high capacitance are better. Examples include X7R, Y5V, and Z5U dielectric capacitors.

For RF applications, low dielectric losses and high Q values are required. Examples include high-Q multilayer ceramic capacitors and SMD chip capacitors.

Special Considerations

When using ceramic capacitors, it is important to consider a few special considerations such as dielectric loss, ESR, and self-healing. Dielectric loss is the amount of energy lost due to the capacitors' dielectric material over time. ESR stands for equivalent series resistance and refers to the resistance of the capacitor when it is in use. Self-healing is a feature of some ceramic capacitors and refers to the ability of the capacitor to repair itself after damage.

Conclusion

Ceramic capacitors are a type of electronic component that uses a ceramic material as the dielectric between two conductors. They are used in a variety of applications, including power supplies, electronics, and automotive. When selecting a ceramic capacitor, it is important to consider factors such as capacitance, voltage rating, and temperature range. Special considerations such as dielectric loss, ESR, and self-healing should also be taken into account. In summary, ceramic capacitors offer many benefits, making them an ideal choice for a wide range of applications.